A good quality windmill aerator can keep your remote water body clear, oxygen-rich, and free from problems like algal blooms, weed infestations, odours, and fish kills.

Our go-to brand is Outdoor Water Solutions (OWS) Windmill Aerators. These are the windmill aerator kits we’ve tested and trust most. They stand apart from the rest for their high-end USA-made design and construction. We know they thrive in tough Australian conditions because we’ve installed them in some of Australia’s harshest environments, from the outback to coastal regions, and they have proved themselves time and again.

Can they survive extreme winds? A little fact is OWS’s manufacturing facilities are located in Springdale, Arkansas, USA–right in the heart of Tornado Alley, one of the harshest wind environments in the world. If they can withstand tornado-force winds there, you can trust they can handle a lot.

Below are the top 8 reasons why the OWS Windmill Aerator is our top wind-powered aerator choice for Australian dams.

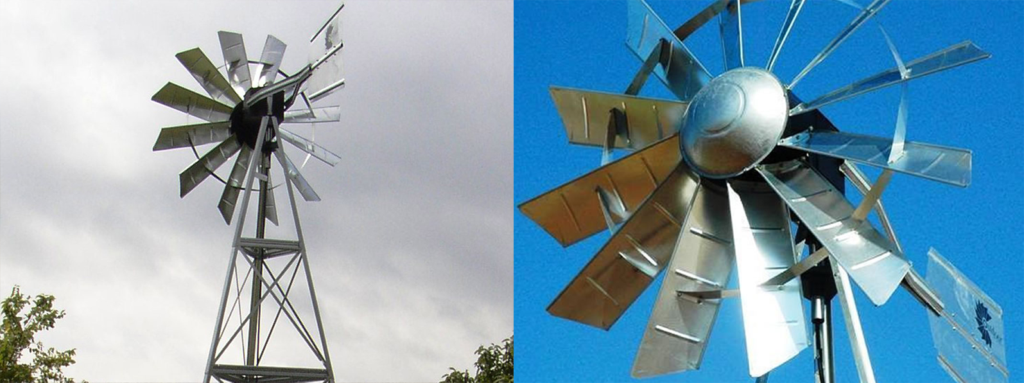

1. Massive Blade Diameter for Low Wind Conditions

Many windmill aerators fail to perform in light breezes, leaving dams without proper oxygenation. The OWS Windmill Aerator solves this problem with a massive 185cm (6 foot) head. Its large surface area captures even the faintest winds, keeping aeration consistent when other windmills stop turning. Continuous aeration, even on calm days, is the key to maintaining stable, healthy water quality.

2. Towering Height to Capture More Stable Winds

The OWS windmill stands at 6m (20 feet) as standard, with the option of adding a 1m extension to reach 7m (23 feet). This towering design places the blades high above ground-level turbulence where winds are stronger and more stable. The aerator works more efficiently by accessing these invisible currents, transferring oxygen into your dam and supporting better water health year-round.

3. Aerates Water Bodies Up to 2 Acres

With its powerful compressor, the OWS Windmill Aerator can effectively aerate dams up to 2 acres in size, provided they are at least 5m deep. In shallower water, the aeration footprint is smaller, but performance remains strong. Sub-surface aeration is particularly effective in deeper dams, where oxygen can be evenly distributed throughout the water column.

4. Self-Governing Head for Extreme Wind Protection

Australian weather is unpredictable, with sudden gusts and violent storms posing real risks to equipment. The OWS Windmill Aerator is built with a self-governing head that automatically adjusts its angle in extreme winds, preventing damage and keeping the system safe. As mentioned above, these systems are built and tested in Springdale, Arkansas, aka right in the heart of Tornado Alley. So this self-governing head is built to endure tornado-force winds.

5. Made in the USA: Built Tough with Premium Materials

Every OWS windmill is built in the USA to the highest manufacturing standards. Constructed from 18-gauge galvanised steel, these windmills are designed to handle years of exposure to sun, rain and heat without compromise. When you invest in OWS, you’re choosing equipment that will last.

6. Designed for Longevity with Minimal Maintenance

OWS windmills are built for the long haul. Using the patented BalCam II Technology, they feature fewer moving parts, bearings, and diaphragms than competing systems. The result is a windmill that requires less servicing and is far less likely to fail. Even in extreme Australian conditions, whether searing summer heat, or winter storms, these windmills continue operating with minimal attention.

7. Industry-Leading 5-Year Warranty on Compressors

The compressor is the heart of any windmill aerator. OWS backs theirs with an industry-best 5-year warranty covering cams and bearings. This guarantee gives you confidence that your aerator will keep working reliably, and if something does go wrong, you’re covered.

8. Simple DIY Installation That Saves on Costs

Professional installation can be expensive, particularly in remote areas. OWS windmills are designed for straightforward DIY setup using modular components and detailed instructions.

Here’s how it works:

- Prepare your site with three concrete footings (or a full slab).

- Assemble the windmill while it’s lying flat on the ground.

- With at least four able-bodied people, lift the windmill into position and secure it to the footings.

This simple process saves you money on labour and ensures you can get your aerator running quickly without specialist tools or expertise.

Summary: Why Outdoor Water Solutions’ Windmill Aerator Is the Clear Winner

Here is a table to summarise:

|

Feature |

Benefit |

|

185cm Head |

Spins in low wind for continuous aeration |

|

Up to 7m Tower Height |

Captures stronger, more reliable winds for maximum efficiency |

|

Aerates up to 2 Acres |

Covers large dams effectively |

|

Self-Governing Head, Tornado Tested |

Protects against storm damage, proven in extreme wind conditions |

|

Made in USA, 18-Gauge Steel |

Unmatched strength and durability |

|

Low Maintenance |

Fewer parts, less servicing, longer lifespan |

|

5-Year Compressor Warranty |

Confidence in reliable long-term performance |

|

Simple DIY Installation |

Saves on installation costs, quick and easy to set up |

Want to Learn More?

The OWS Windmill Aerator is trusted by farmers and landowners across Australia because it delivers reliable, long-term aeration with minimal maintenance.

Learn more here: OWS Windmill Aerator

Get FREE Advice

Or, get FREE expert advice here. We’ll provide personalised, no-obligation guidance on what windmill aerator kit you’ll need and the steps involved, as well as other options available to you, e.g. solar aerators.